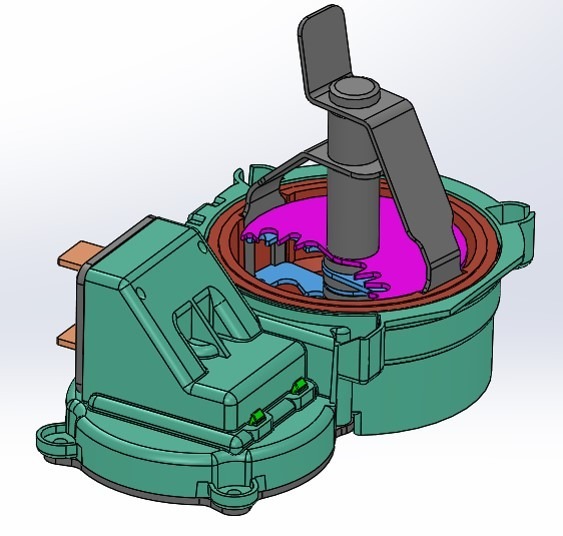

Taurus Aero designs and manufactures cutting-edge actuators, propulsion systems, and Control Moment Gyroscopes (CMGs) for aerospace and space applications. Our solutions feature proprietary PATENTED Taurus Electric Motors, Electronics, and Magnetic Bearings, delivering unmatched precision, zero-backlash performance, and high-efficiency energy management.

AERO

propulsION & actuation

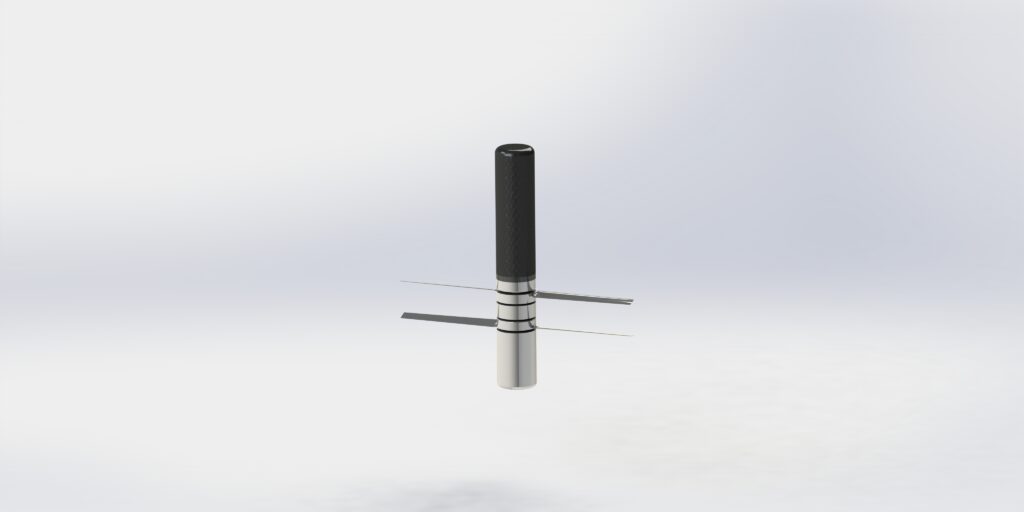

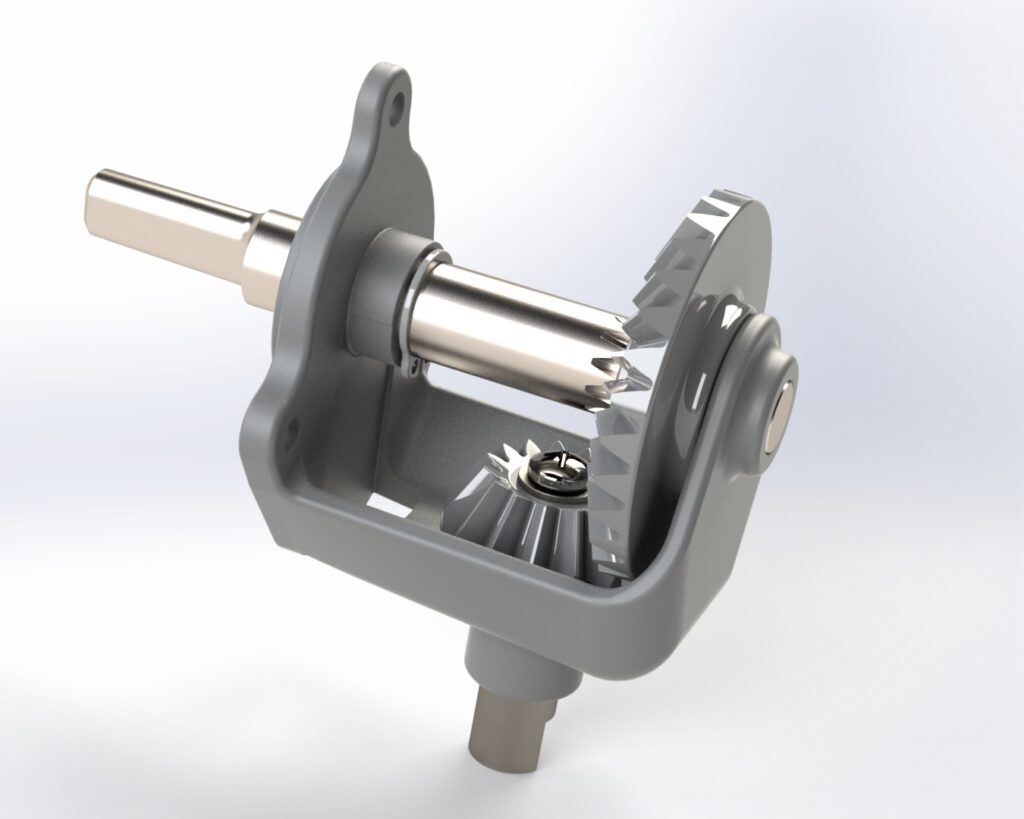

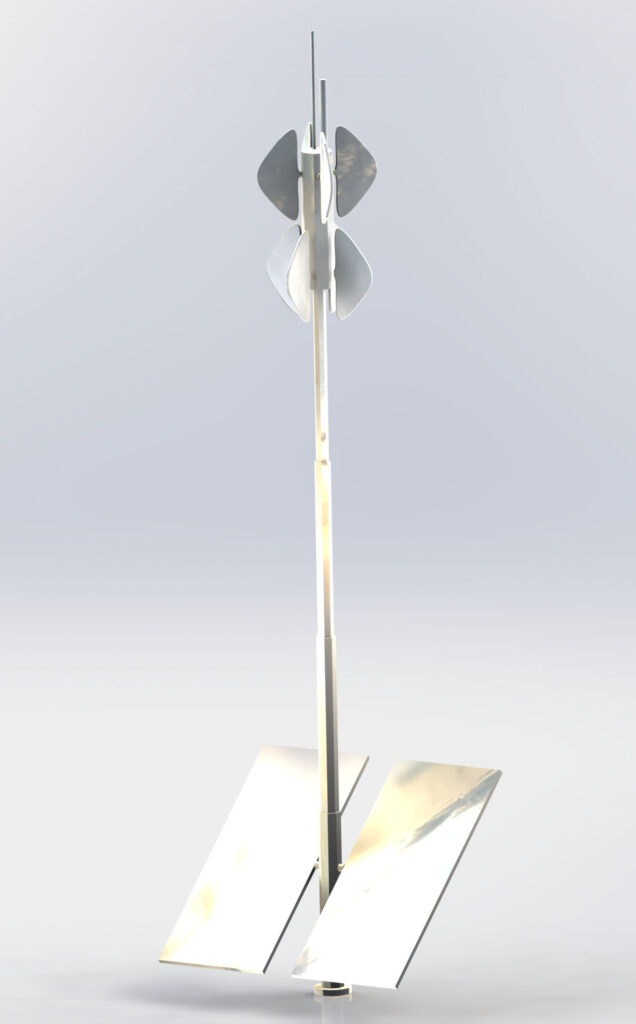

Image: The first in the world printed Titanium turbine rim driven propulsion fan, designed and manufactured by Taurus.

Immense. Positive. Impact.

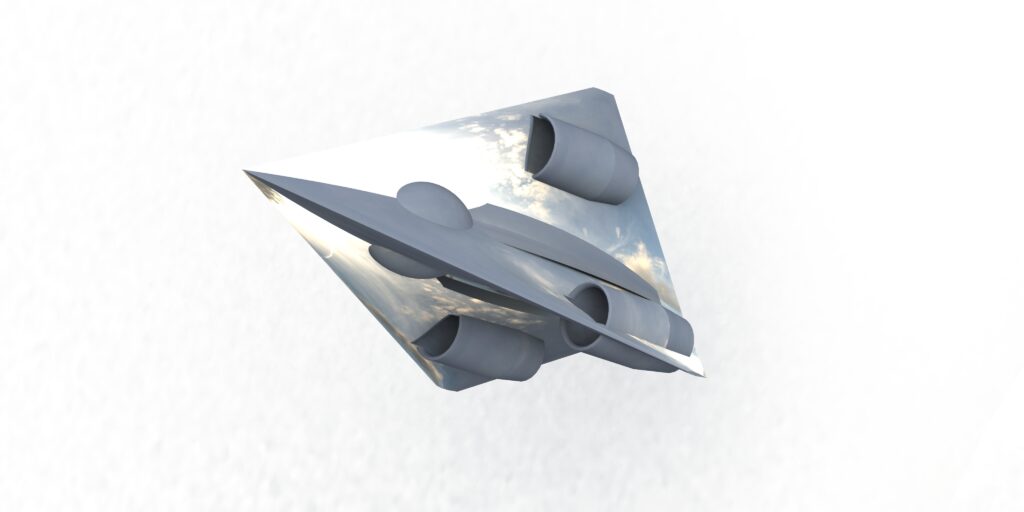

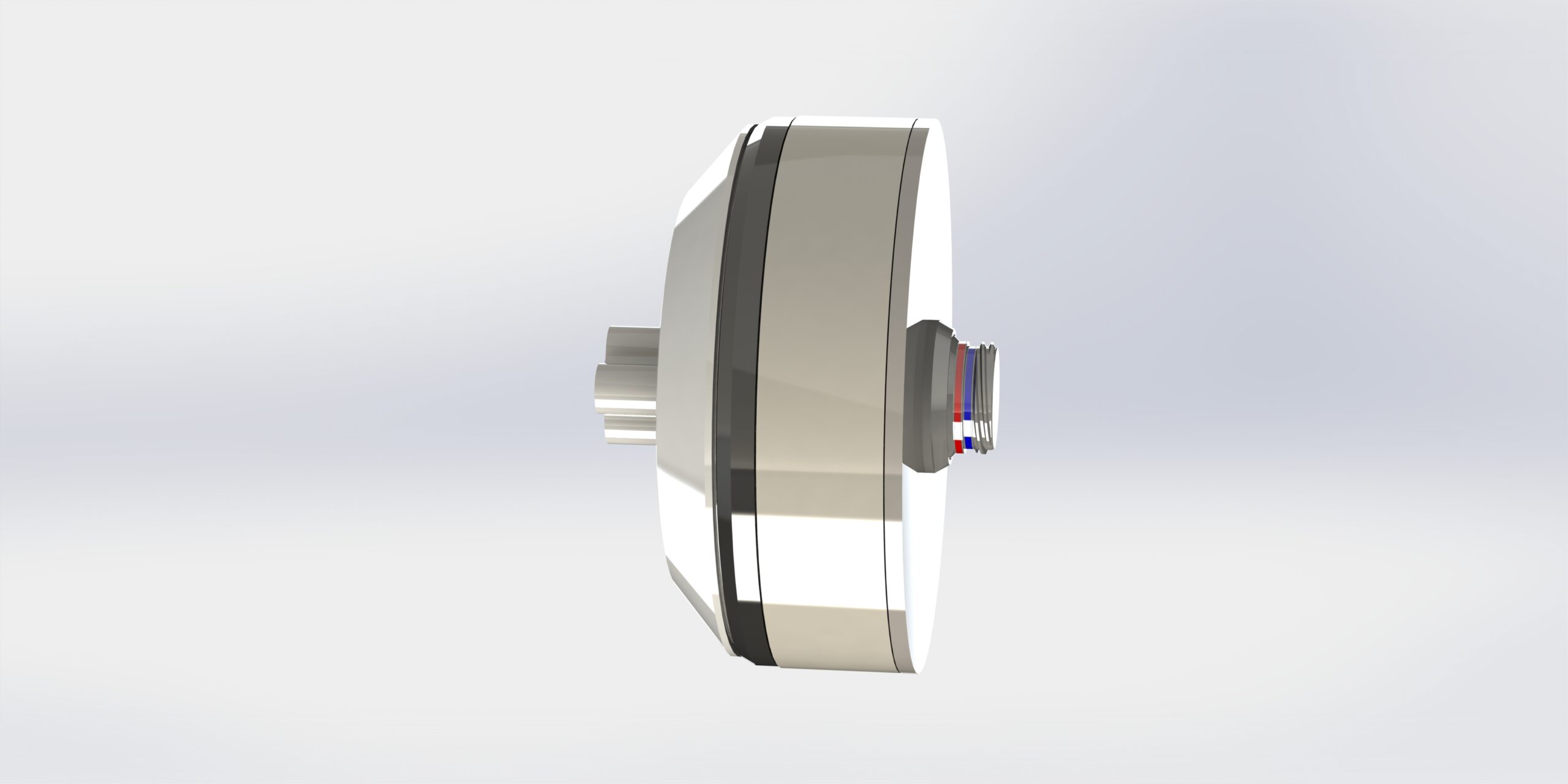

Taurus Motors, a fully patented technology, is transforming the aviation industry with ultra-efficient, high-torque propulsion featuring zero-back EMF. Its seamless integration with zero-backlash gearing ensures unmatched precision, agility, and reliability in flight control and actuation systems, setting a new standard for aerospace performance.

The efficiency of Taurus Motors in aviation translates to significant economic benefits by reducing fuel consumption, lowering maintenance costs, and increasing aircraft lifespan. With higher energy efficiency and zero-backlash precision, aircraft can operate with reduced power losses, leading to lower operating expenses for airlines and defense sectors. The durability and reliability of Taurus Motors also minimize downtime and maintenance needs, cutting repair costs and extending service intervals. Additionally, the improved performance allows for lighter, more agile aircraft, enhancing payload capacity and overall profitability. These factors collectively drive substantial cost savings and operational advantages across the aviation industry.

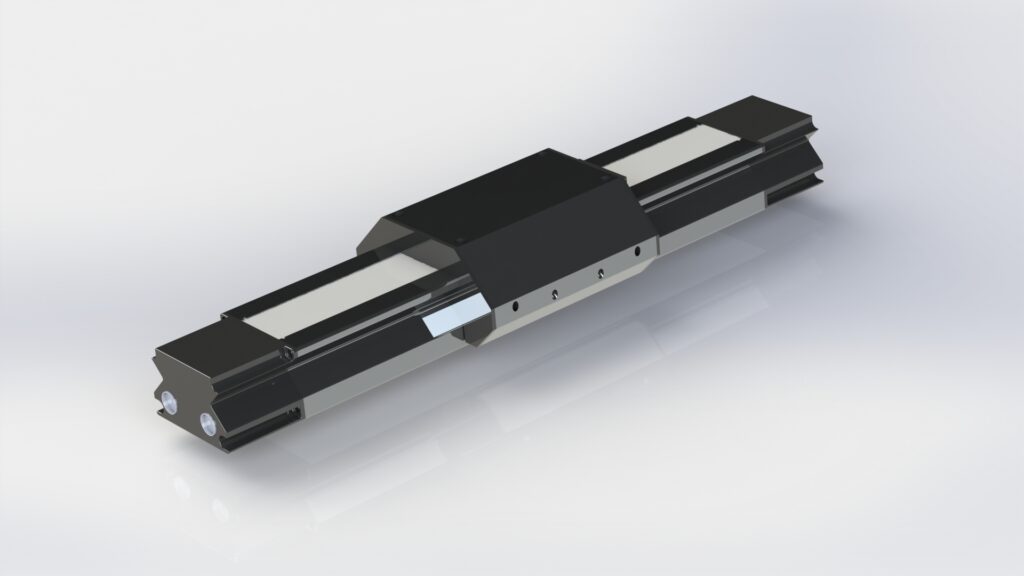

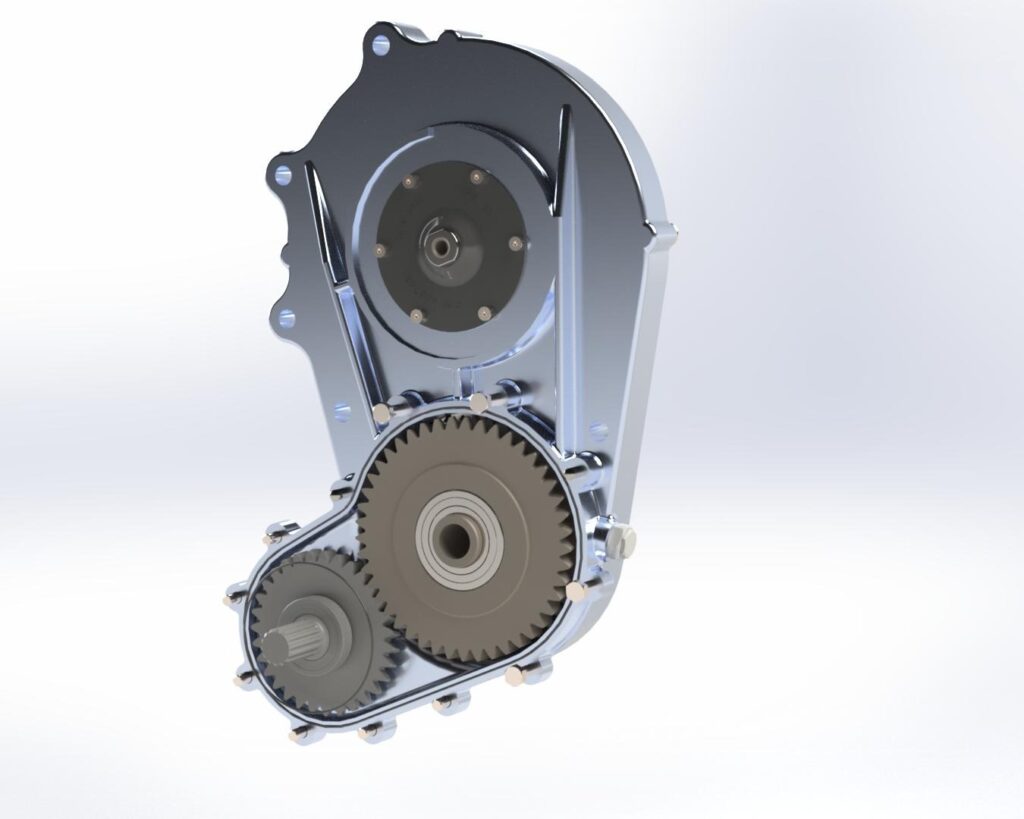

Our zero-backlash gearing system integrated with a Taurus motor offers unparalleled precision, efficiency, and reliability

No Back EMF

Enables seamless control and operation at any speed without torque ripple or instability.

Unlimited Speed Range

Operates efficiently at both low and ultra-high RPMs, making it suitable for a wide range of applications.

High Torque Density

Provides superior power output relative to size, reducing system weight and footprint.

Ultra-High Efficiency

Minimizes energy losses, leading to lower power consumption and heat generation.

FLIGHT IS ABOUT EFFICIENCY OF MOTION

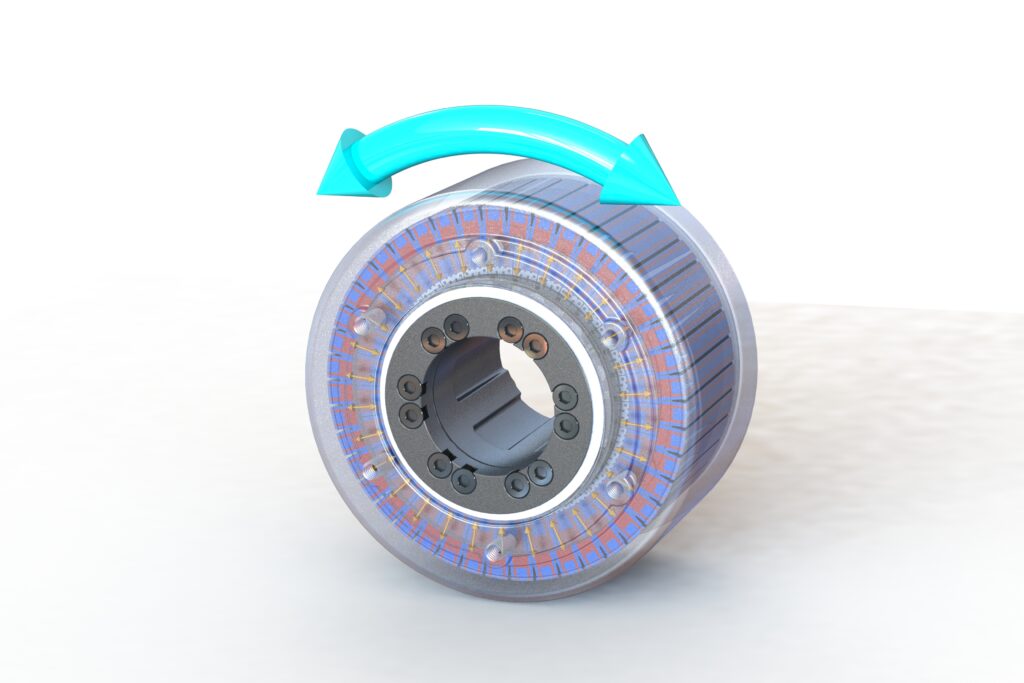

Taurus Electric Motor

Technical Benefits

Advanced Thermal Management: Optimized for high-performance operation in extreme environments.

No Back EMF: Enables seamless control and operation at any speed without torque ripple or instability.

Unlimited Speed Range: Operates efficiently at both low and ultra-high RPMs, making it suitable for a wide range of applications.

High Torque Density: Provides superior power output relative to size, reducing system weight and footprint.

Zero-Backlash Integration: When combined with Taurus gearing, ensures precise motion control with no lost motion.

Ultra-High Efficiency: Minimizes energy losses, leading to lower power consumption and heat generation.

Robust & Scalable Design: Adaptable for various aviation, industrial, and space applications with customizable configurations.

Economic Benefits

Reduced Energy Consumption: High efficiency leads to lower fuel and electricity costs in aviation and industrial applications.

Lower Maintenance Costs: Low vibration, no sparks and AI monitoring minimizes repair frequency and operational downtime.

Increased Aircraft & System Longevity: Reduced mechanical stress and vibrations enhances component durability and service life.

Optimized Manufacturing & Integration: Simplified system architecture lowers production costs and assembly complexity.

Enhanced Payload & Fuel Savings: Lightweight, high-efficiency motors reduce overall system weight, leading to improved energy economy.

Higher ROI & Competitive Advantage: By leveraging reduced energy consumption, lower cost of ownership, and enhanced performance, Taurus delivers significant financial and operational benefits across industries.

A passion for motion

We believe that motion should be seamless, controlled, and powerful—whether it’s enabling a satellite to reposition with pinpoint accuracy, a robotic arm to move with human-like dexterity, or a high-torque actuator to operate under extreme conditions.

Your Challenges Drive Our Innovation

At Taurus, our clients’ challenges are the reason we exist. Every system we design, every breakthrough we achieve, and every product we deliver is driven by a singular purpose—to solve the toughest motion challenges with precision, efficiency, and reliability.

Continuous Support

Our commitment doesn’t end with delivering cutting-edge motion solutions—it continues through every phase of your journey. We believe that true innovation is backed by reliability, expertise, and unwavering support.

Our CEO and founder’s motto

“Everything spins or wants to spin”

Sounds silly at first, yet it holds true on micro and macro scale.

Consulting

We have provided expert consulting for over two decades, helping our clients overcome challenges, optimize performance, and push the boundaries of what’s possible.

OEM Project Client Management

With us, your OEM project is more than a contract—it’s a partnership built on innovation, execution, and long-term success.

No Box Solutions

Traditional constraints don’t define us. Instead, we take a first-principles approach, re-imagining motion solutions from the ground up to deliver breakthrough performance, efficiency, and precision.

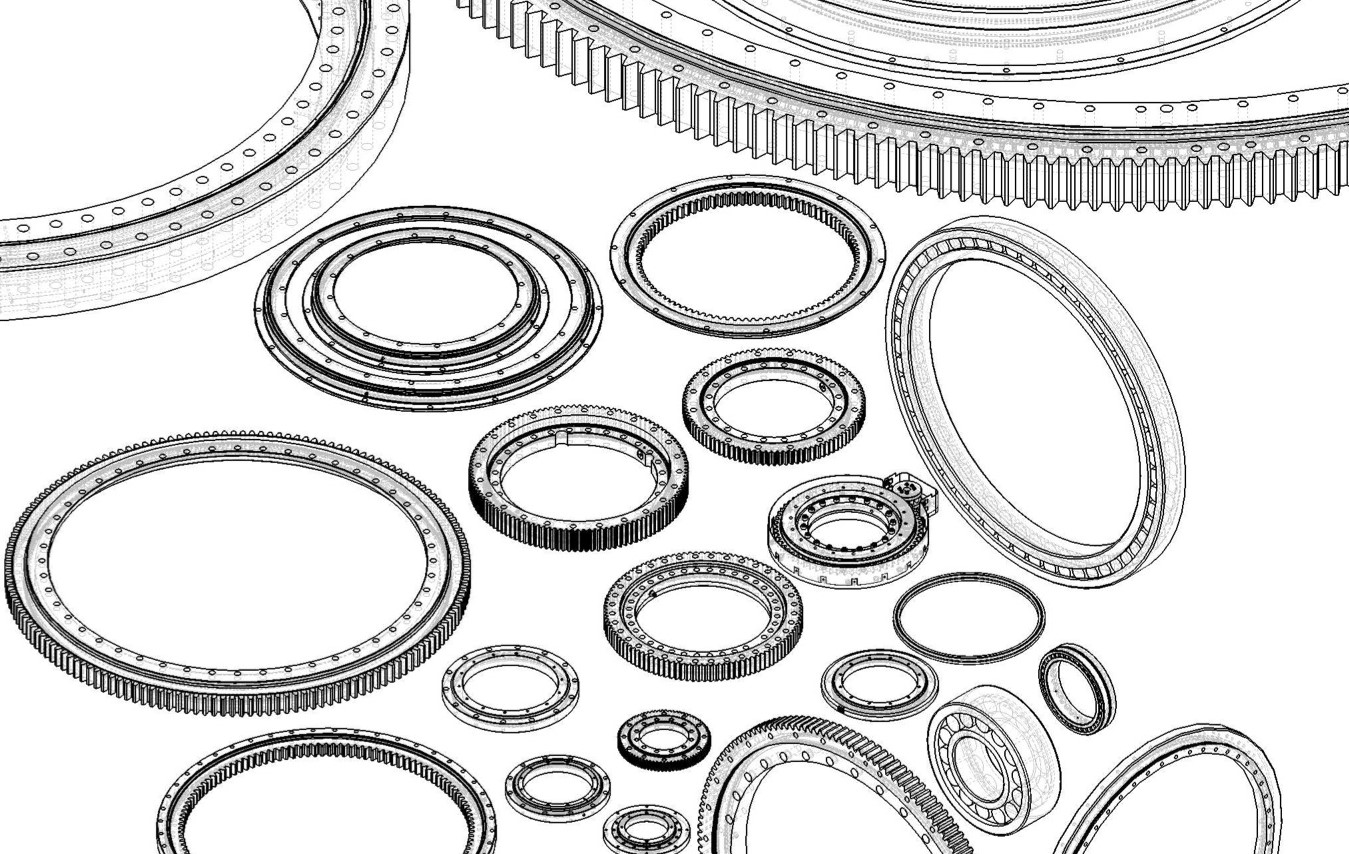

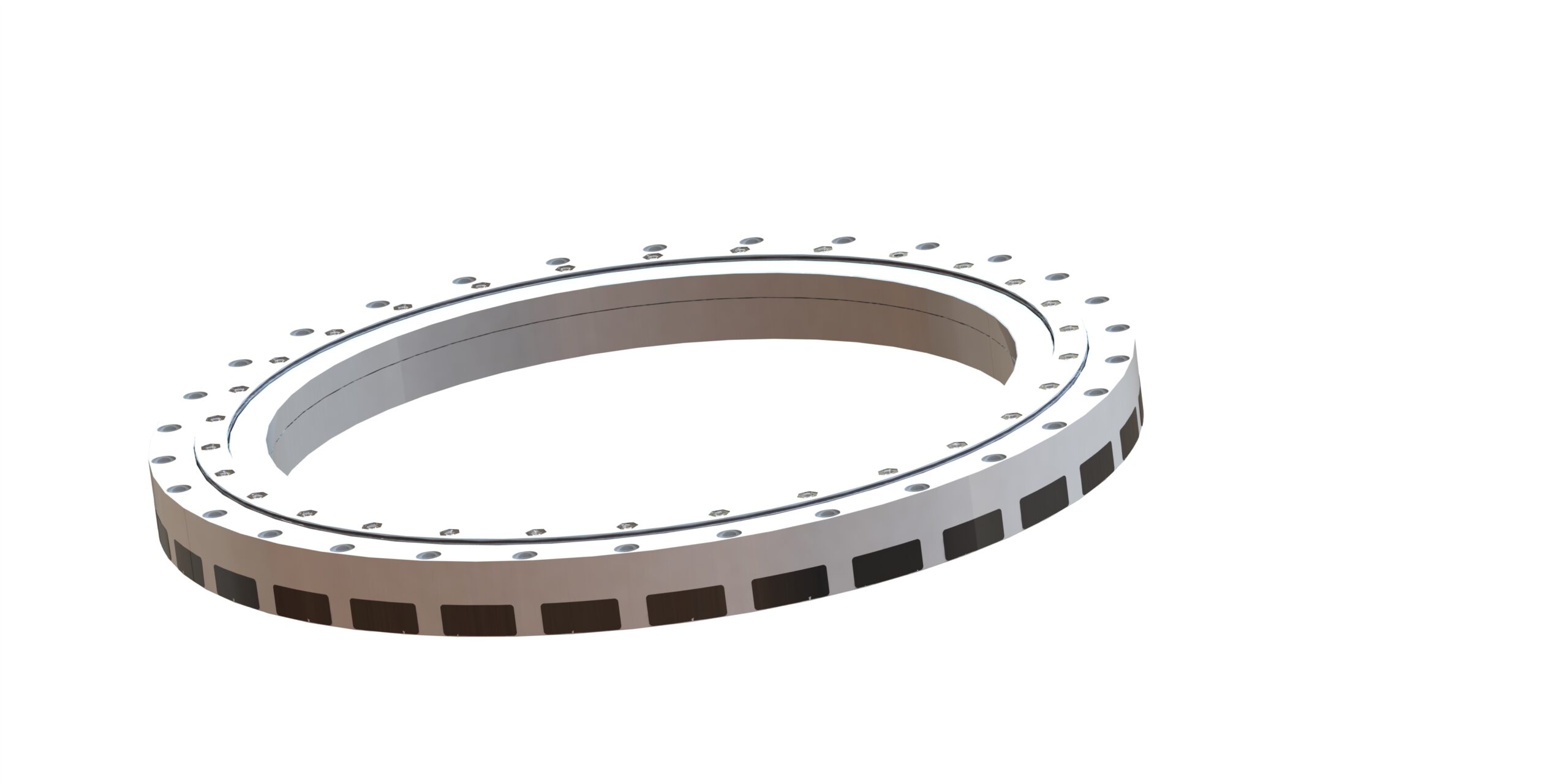

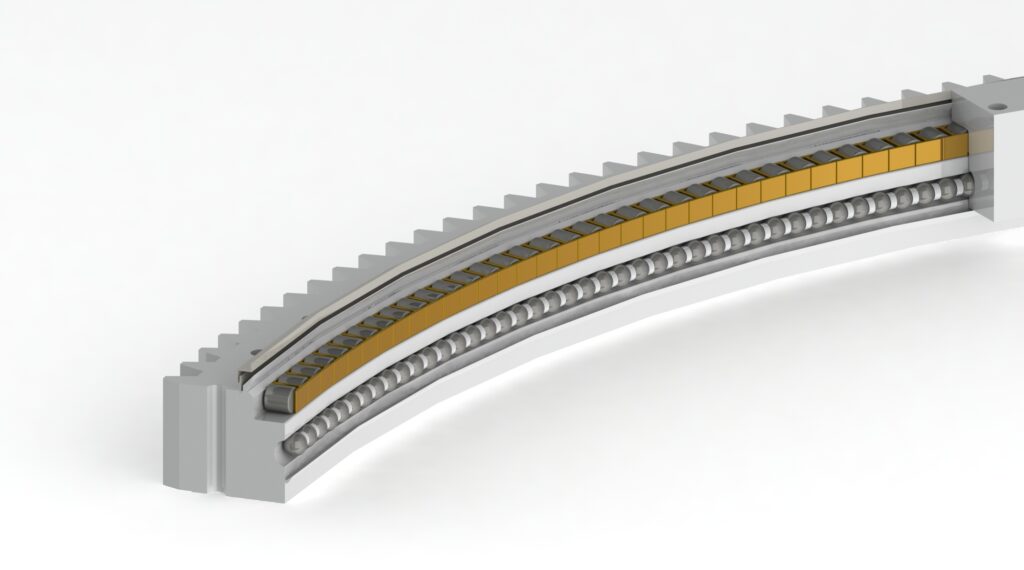

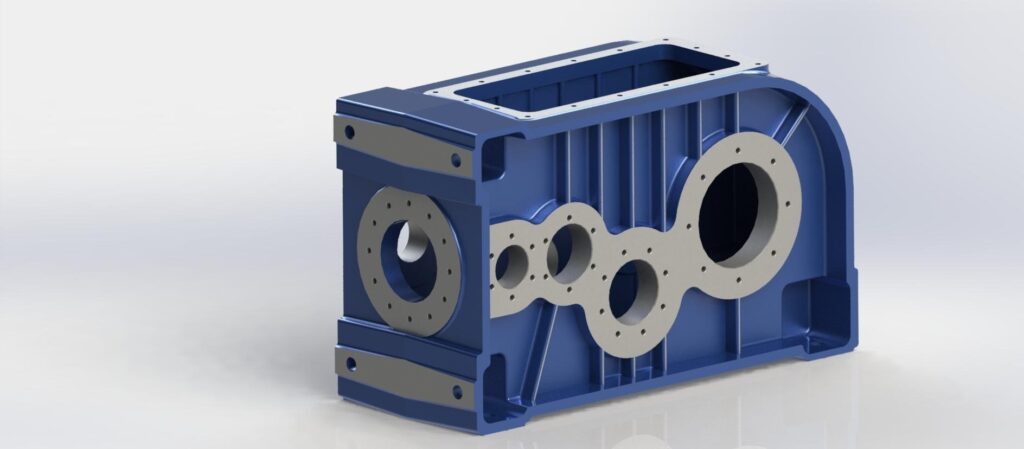

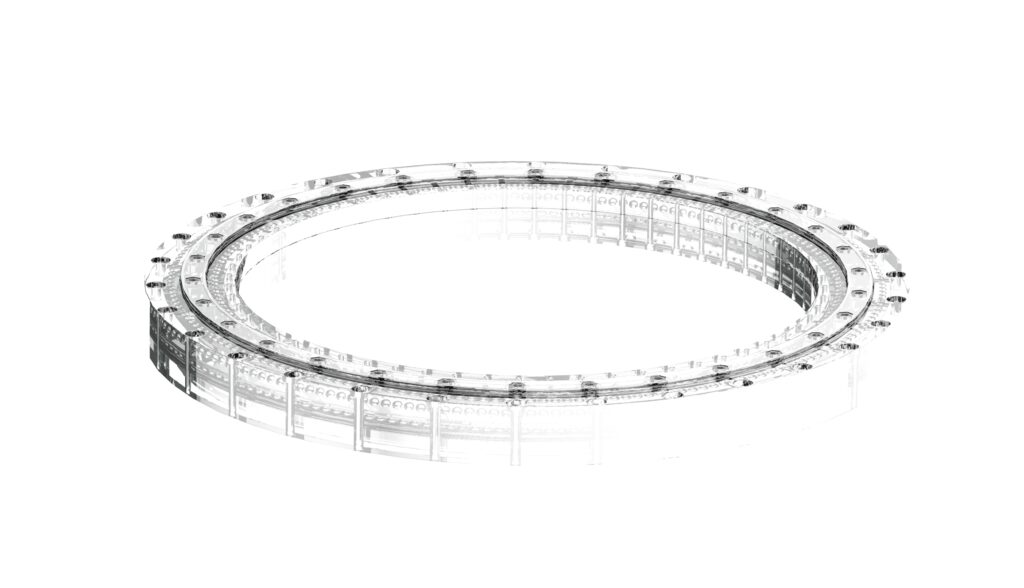

TAURUS BEARINGS & DRIVES

For over 20 years, Taurus has been at the forefront of bearing design and precision manufacturing, delivering industry-leading solutions that redefine performance, reliability, and efficiency.

Taurus continues to push the boundaries of bearing technology, delivering next-level performance for the toughest motion challenges.

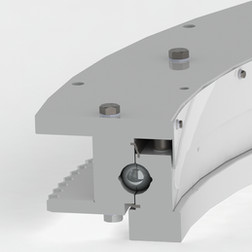

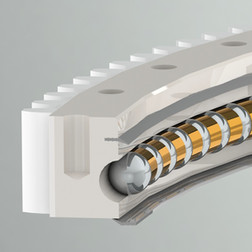

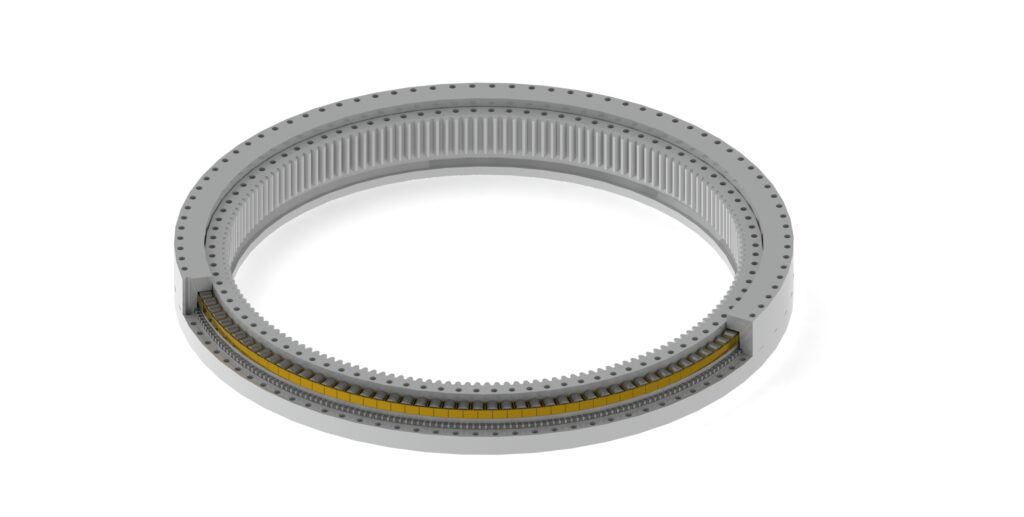

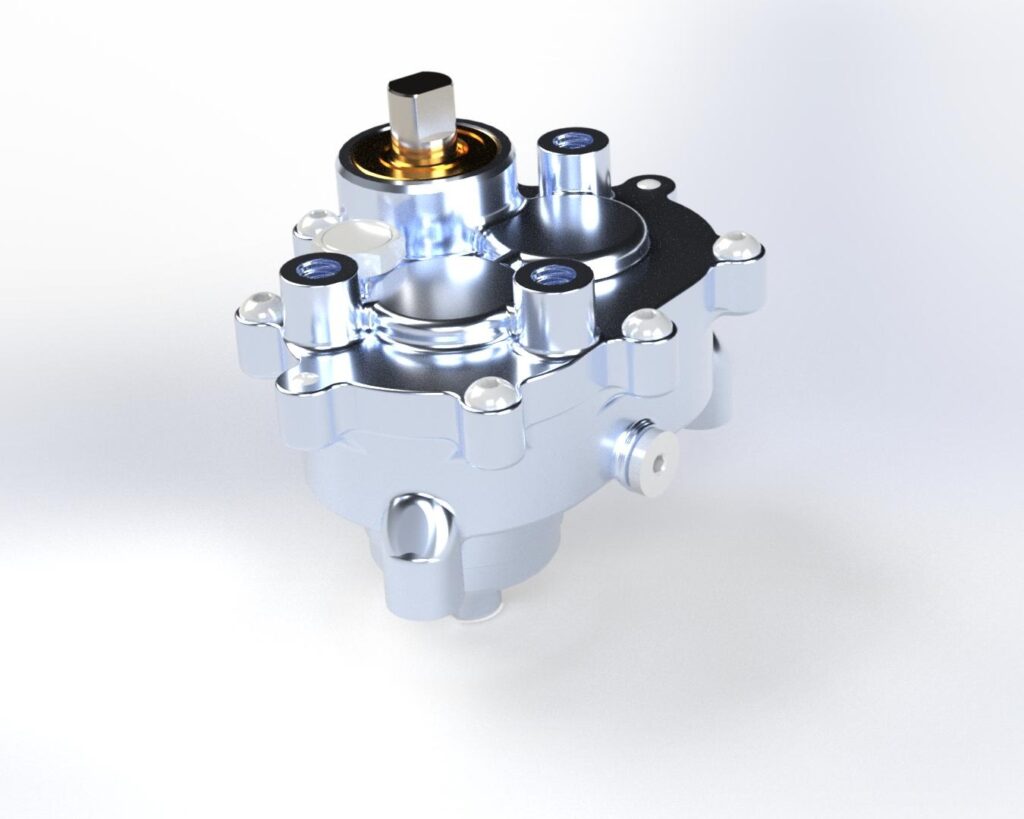

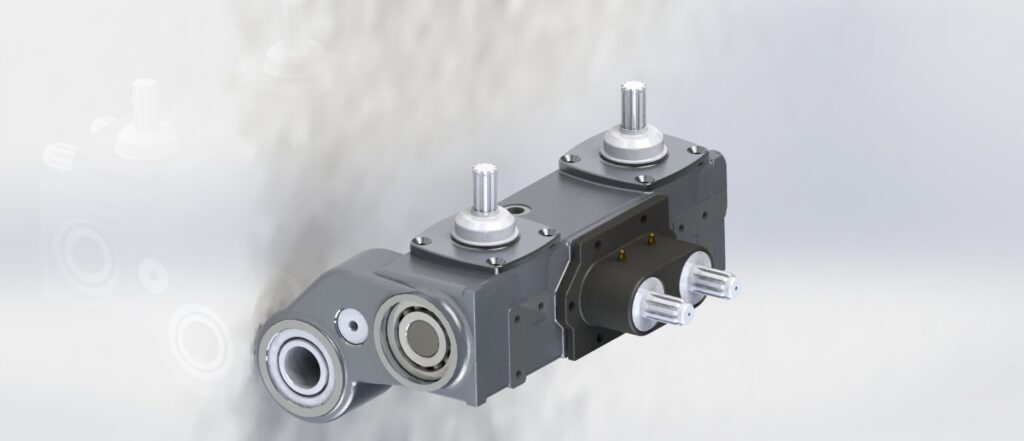

Taurus custom bearing slew drives are engineered for high-precision, high-load applications where durability, accuracy, and reliability are paramount. Integrating proprietary Taurus Spherigear and Taurus Bearings technologies, these systems deliver true zero backlash and ultra-high efficiency, ensuring smooth motion control in demanding environments. With high torque density for precise positioning, a compact design supporting heavy axial, radial, and moment loads, and integrated braking and locking systems for safety-critical applications, they offer unmatched performance. Built for extreme durability, Taurus slew drives excel in harsh conditions across aerospace, robotics, and industrial automation.

TAURUS MECHANO

Motion isn’t just what we build—it’s who we are.

TAURUS MECHANO

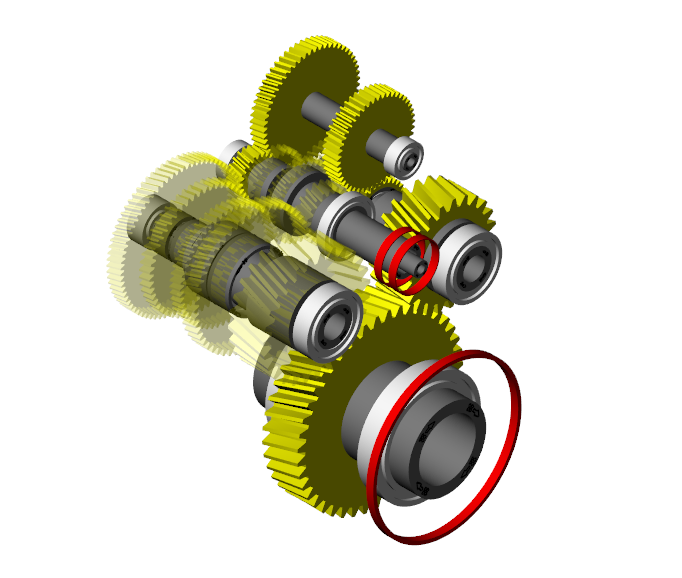

Key Advantages of the Spherigear & Motor Combination:

Zero Backlash & True Precision

The Taurus Spherigear eliminates backlash through its unique, proprietary geometry, ensuring precise motion control.

When paired with Taurus Electric Motors, it enables ultra-smooth actuation with high positional accuracy.

High Torque Density & Compact Design

The Spherigear’s unique load distribution allows for higher torque transmission in a smaller form factor.

Combined with the Taurus Electric Motor’s proprietary electromagnetic design, it delivers maximum power-to-weight efficiency.

High Efficiency & Reduced Loss

Unlike conventional gear systems, the tech reduces friction losses, improving system efficiency by reducing the part count.

The motor’s low-loss design ensures optimal power utilization, extending operational endurance of the entire system.

Extreme Durability & Longevity

The tech utilizes high-strength materials and optimized surface treatments, making it resistant to wear, shock loads, and high-speed operations.

The motor’s advanced thermal management prevents overheating, ensuring long-term reliability in demanding applications.

Gearboxes & Actuation Systems

The combination provides a fully integrated drive solution, eliminating the need for complex gear reduction stages.

Allows for direct-drive or reduced-stage gear configurations, reducing overall system weight and size and efficiency.

Scalability & Customization

Available in multiple torque ratings and sizes, from precision micro-actuators to high-power industrial actuators.

Custom control electronics and software allow for fine-tuned performance, including high-speed rotation, torque control, and dynamic response.

DETECTION AND DEFEAT

NEXT GENERATION RF SECURITY. DETECTION. DEFEAT.

NOX: Next-Level AI Security for SCADA RF Communications

At Taurus, security isn’t just an afterthought—it’s engineered into every signal. NOX is a holistic AI-driven security solution that protects SCADA RF communications, ensuring next-level resilience against cyber threats, RF interference, and drone incursions.

- Detects & Defeats RF Drones – Identifies and neutralizes unauthorized RF threats before they can compromise your system.

- 30% More Data Transmission – Optimized RF efficiency for faster, more reliable SCADA communication.

- Seamless Legacy Integration – Plug-and-play compatibility with existing infrastructure for zero downtime implementation.

- Nefarious RF Signal Passivization – Identifies, isolates, and neutralizes rogue transmissions, ensuring uninterrupted operations.

With NOX, your RF communications become smarter, faster, and virtually impenetrable—because in today’s world, security isn’t optional, it’s essential.

With meticulous attention to detail and a commitment to excellence, we create systems that elevate, and enrich the lives of those who use them

As new paradigms shift the status quo, we are set to redefine the landscape of innovation, serving as a nexus of precision engineering, cutting-edge motion solutions, and industrial security. Our unwavering commitment to advanced technology honors our rich legacy while embracing the future, ensuring that Taurus remains a beacon of reliable, high-performance systems—empowering industries, driving progress, and enriching lives with every breakthrough we achieve.

AERO ELECTRIC BEARINGS MECHANO NOX

Guiding your business through the motions

Experience the fusion of imagination and expertise with Taurus—the catalyst for motion transformations that enriches the world around us

We work with some of the best companies.

FAQs

What is your process working in smaller projects?

At Taurus, we approach smaller projects with the same level of precision, innovation, and commitment as our large-scale developments. Our process is designed to be efficient, flexible, and client-focused, ensuring that even smaller-scale solutions receive custom engineering and high-performance results.

Who is behind Taurus?

Taurus is powered by a team of highly skilled professionals, each bringing expertise in key areas of motion systems, actuation, and RF security. With backgrounds spanning aerospace, defense, robotics, energy, and industrial automation, our team has a proven track record of innovation, holding numerous groundbreaking patents that have shaped their respective fields. This depth of expertise enables Taurus to deliver next-level engineering solutions that redefine performance, security, and reliability.

How does Taurus ensure reliability in extreme environments?

Our technologies are built for the most demanding conditions—space, defense, and high-performance industrial settings. Every system undergoes rigorous testing for temperature extremes, vibration, shock, and radiation to ensure unmatched durability and precision.

How can I integrate Taurus technologies into my existing system?

We design our solutions with flexibility in mind. Whether you need a standalone unit or a fully integrated system, we provide adaptable interfaces and expert support to ensure seamless integration with your platform.

Enhance your journey with Taurus.

- Collaborate with fellow tech gurus.

- Take your projects to the next level.

- Experience the world of tomorrow, Today!